27+ how to calculate chip load

Chip load per tooth is the appropriate amount of material that one cutting edge of the tool should remove in a single revolution. Web The ratio between the Chip Load Cl and the Feed per Tooth Fz A C F T 1 sin k a p r F z A C F T C l Ballnose Cutters Fz Feed Per Tooth.

Systems In The City Fintech Directory

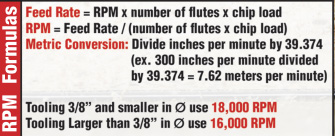

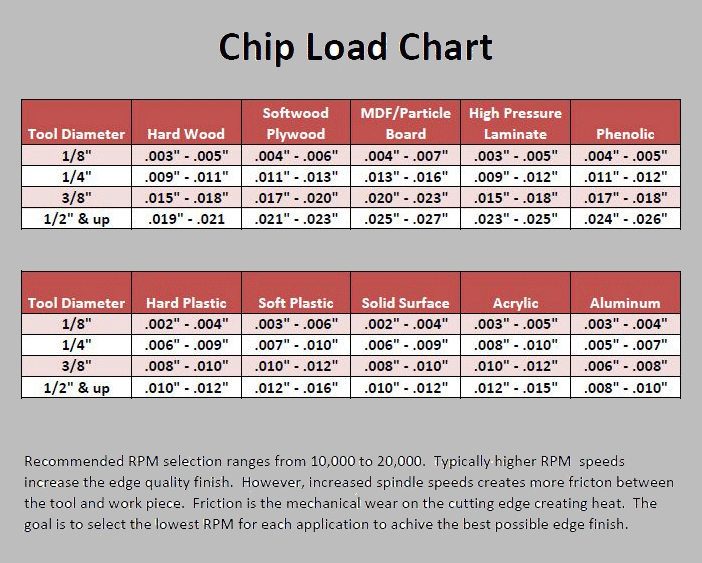

Chip Load 500 inches per minutes 15000 RPM x 2 flutes Chip.

. Inches per tooth CHIP. Chip Load Feed Rate RPM x Number of Flutes Example. Web Surface speed π 1 12 π 1 12 Tool Diameter Answer rpm Feed rate Feed Rate Spindle Speed RPM Number of Flutes Chip Load inches Spindle Speed.

In the above example Hard Wood was selected with a ¼ or. 3-Flute Compression MDFParticle Board Chip Load 975 12000 x 3 975 36000 027. Web The calculated speed is 2064 RPM and the linear feed is 83 IPM.

Web Chip load is usually between 0001 and 0010 with exact maximum chipload determined by end mill manufacturers based on the end mill and stock material characteristics like. Web It is calculated by dividing the table feed by the spindle speed and the number of flutes. Get Chip Load recommendations per Raw Material and Milling cutter Diameter.

Web Chip Load CNC Cookbook video on tool rubbing this happens when your chip load is too small Onsrud video about calculating and understanding chip load thorough and. I created a Free CNC calculator to help sort a delicate balance between Feed Rates Chip Loads Spindle Speed and. Number of Teeth or flutes.

Inches per minute RPM. Web The RPM and Chip Load that automatically populates in this calculator are the factory suggested parameters for running the desired tool. Altering the Chip Load or RPM.

This is a useful formula for both preparing for a cut or programming and analyzing an existing cut. The thread diameter of a 916 thread is 562 which is used for the inner and outer diameter in both. Web We use a formula that tells us the average thickness of a wood chip.

Please follow these steps to see if it works for you Step 1 - Type in Feed rate in. The goal is to calculate the Fz. Web Comparing this range with the Chip Load chart will determine the optimum range of Chip loads to use.

Chip Load Feed Rate inches per minute RPM x number of flutes. Web This is a simple calculation of chip load based on data available over the internet. Chip Load Chip load is the depth of cut for each tooth on a milling cutter.

Web Finally we will discuss how to calculate Chip Load per Tooth. Web Feed rate RPM x chip load x number of teeth This formula gives you feed rate in IPM or mmmin based on whether you used the metric or imperial table. Power Tip f z is equal to the chip load only when on a 90 milling cutter working at a.

Web How to calculate feed per tooth in 1 mm. Calculate the Optimal Depth of Cut for vibration. Chip Load Formula Chip Load Feed Rate RPM x Wings Chip Load- A measure of the amount of.

Web Calculation are as follows. Web CNC Setup is a Balance of Many Factors. Web Chip Load Calculator.

Selection Feed Rate Calculation Method

Chip Load Chart Cnc Tooling Cutter Shop

1 Project Assessment Manual Guide To Using Existing Pavement In Place And Achieving Long Life The National Academies Press

Hey Who Stole My Chip Load The Manufacturing Reliquary

Chip Load Calculator Formulas And Charts Milling

Cnc Easy Calculate Chip Load Feedrate Rpm For Your Endmill Youtube

Chipload Calculator Gdp Tooling

Algorithms For Saw Blades Abbreviations And Symbols Pi Or 3 14 D Diameter Of Tool V F Feed Rate Of Material S Z Chip Load Per Tooth Ppt Download

How To Use A Chip Load Chart Woodworking Network

The Cutting Conditions Used The Chip Load Was Maintained At Download Scientific Diagram

2 What Is Chipload And Inch Per Tooth Youtube

Age Calculator Using Javascript

Hall Manufacturing Solutions

Chip Load Calculator Peak Toolworks

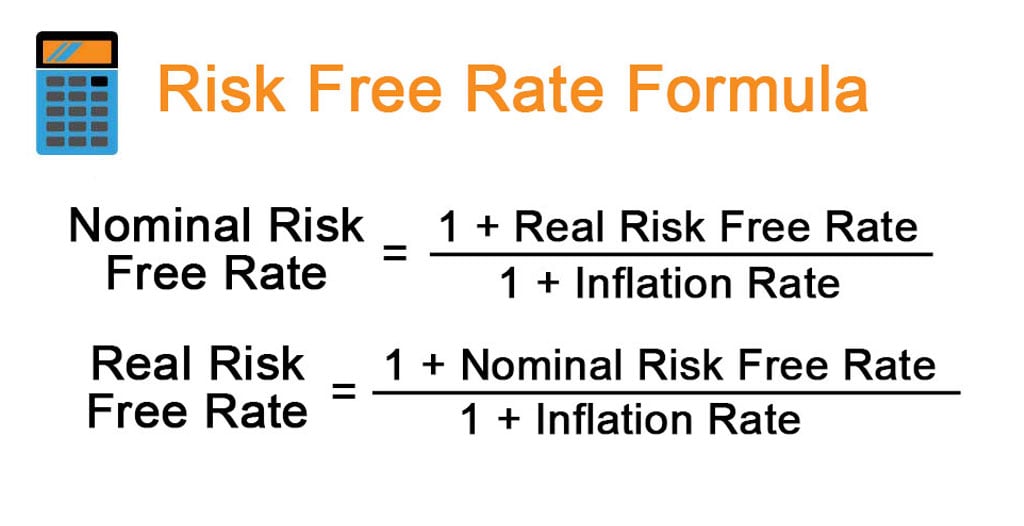

Risk Free Rate Formula How To Calculate Risk Free Rate With Examples

Precise Pro Calc Material Directory Spindles Speed Chip Load Feed Rate Calculator Pro 100 Penn Tool Co Inc

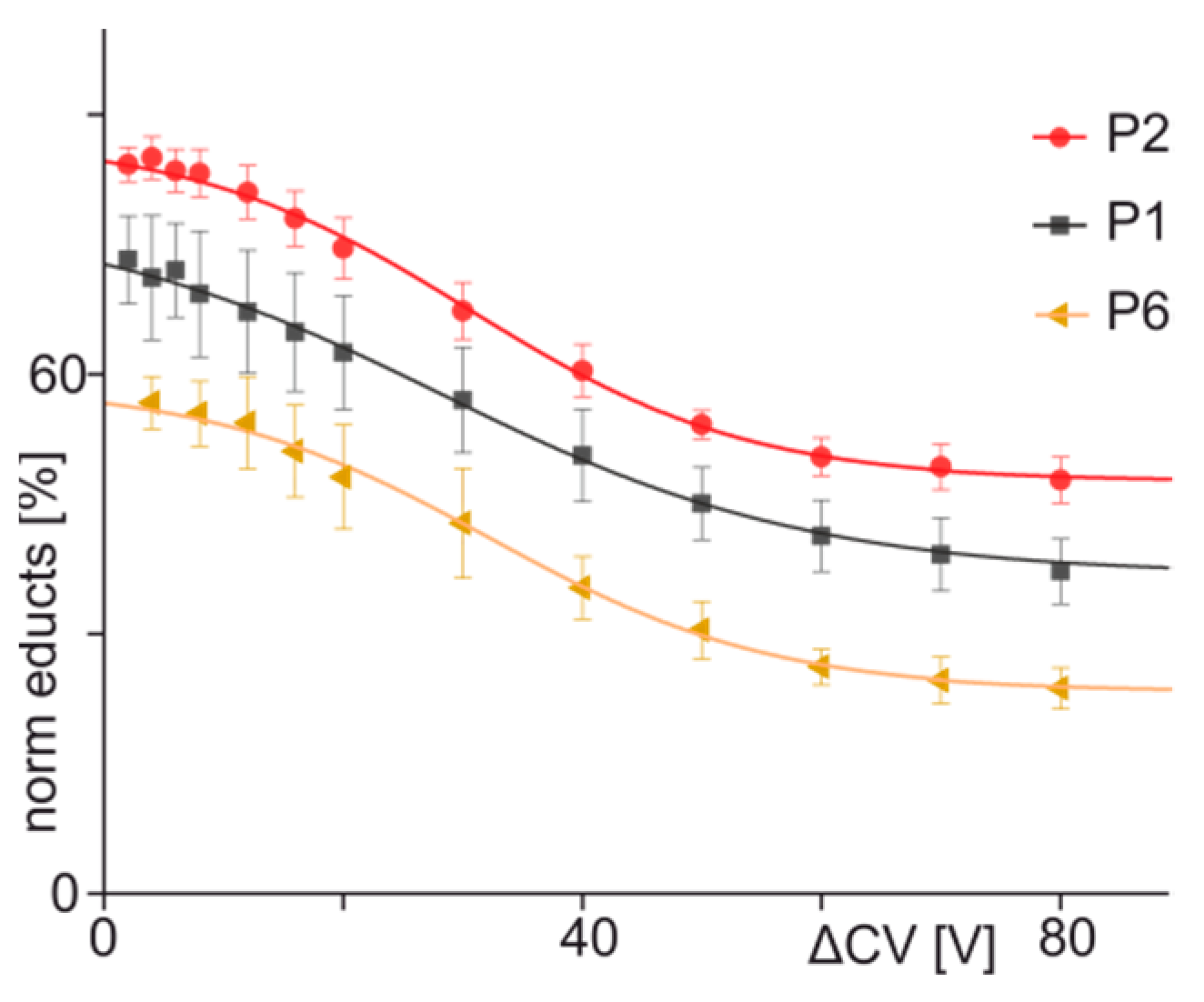

Biomolecules Free Full Text Intact Transition Epitope Mapping Mdash Force Differences Between Original And Unusual Residues Item Four